We use computer-controlled (CNC) machining to create precision-machined parts, such as engine turbines and components for a wide range of industries. Our CNC machine shop is state-of-the-art and gives us the capability to produce consistently precise and accurate parts, which has earned us our continued success throughout the years. Here’s a quick guide to machining […]

We use computer-controlled (CNC) machining to create precision-machined parts, such as engine turbines and components for a wide range of industries. Our CNC machine shop is state-of-the-art and gives us the capability to produce consistently precise and accurate parts, which has earned us our continued success throughout the years.

Here’s a quick guide to machining manufacturing operations and processes, as well as the most common techniques and tools used in this industry.

DIFFERENT TYPES OF MACHINING

“Machining” refers to the different manufacturing processes that are completed using special tools that use precision to carve or build an equipment component. The two main types of machining are additive manufacturing and subtractive manufacturing.

ADDITIVE MACHINING

The additive process usually involves the use of a 3D printer working with plastic. The printer builds layer upon layer to gradually achieve the desired shape or form. This creates a precise, lightweight, and durable part built to the exact specifications that the computer software has provided.

SUBTRACTIVE MACHINING

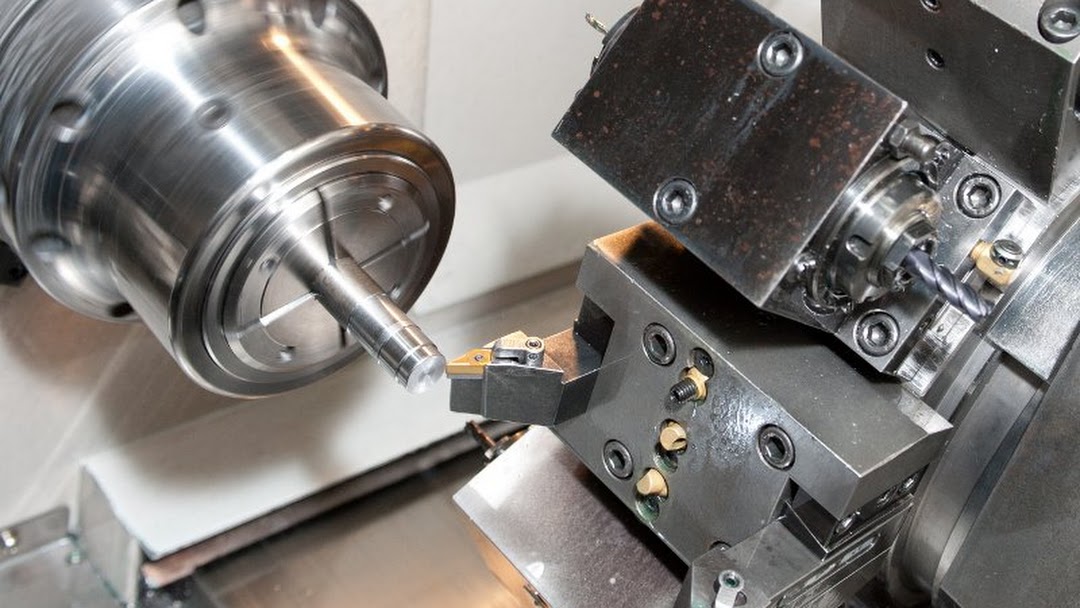

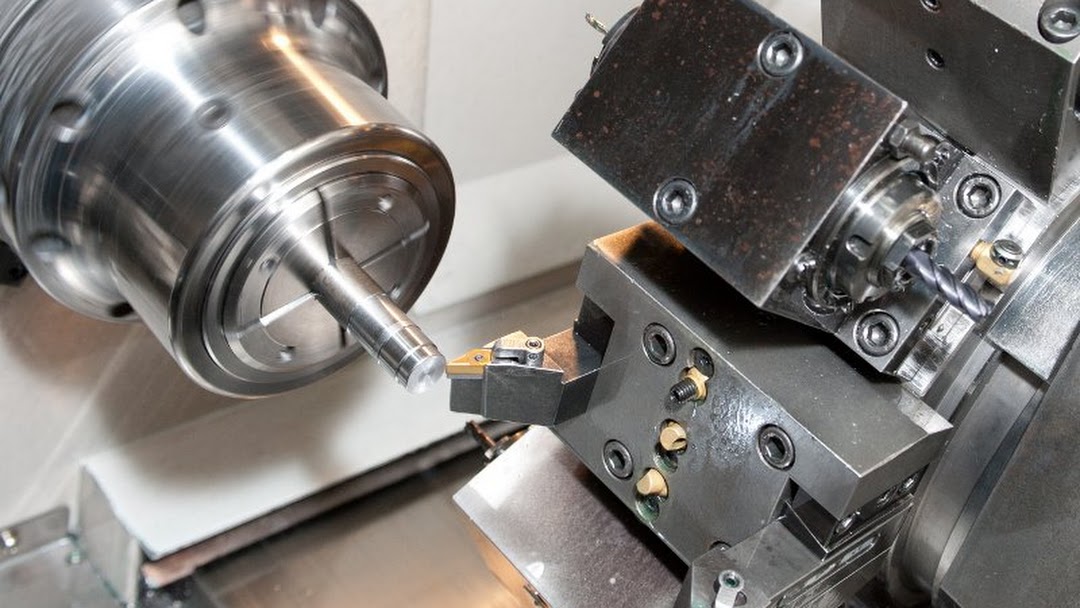

The subtractive process essentially removes unwanted material from a block of material (a “workpiece”) using cutting tools to build a specific part. It starts with a blank workpiece, typically made of metal or an alloy, but sometimes plastic.

There are two different methods. In the first method, the workpiece itself rotates against a cutting tool, which carves it. In the second method, the workpiece is held still while the tool rotates at high speed to remove excess material to reveal the intended shape of the end product. This process effectively removes material layer by layer, hence the name “subtractive.”

CNC MACHINING OPERATIONS

CNC machining is a specific type of manufacturing that marries the advanced technology of computers with machining tools.

The process works by using those machine tools to shape and contour a workpiece to follow specific parameters or client instructions. The benefit of this machining technique is that it eliminates the risk of human error since advanced software does all the work.

In fact, it only requires a minimum of human labor and allows for efficient machining and processing, even for intricate parts and components. It also allows us to create consistently uniform and reliable pieces that can withstand the extreme pressures of this industry.

DIFFERENT TECHNIQUES IN THE MACHINING MANUFACTURING PROCESS

CNC machines use different machining techniques to create endless design variations of parts and materials for numerous industries and applications. Some of the most common machining processes include milling, drilling, turning, laser cutting, EDM (Electric Discharge Machining), and grinding.

MILLING MACHINING OPERATIONS

CNC miling machience operations use various multi-point tools to achieve varying techniques, like slab milling or face milling. The process involves using a milling machine that has free-moving tables. The workpiece stays securely mounted on top for milling with subtractive manufacturing methods.

Once the workpiece is in place, the table rotates it against cutters at a high cutting speed, which removes any material that’s not part of the final component. Essentially, this technique uses the table to move the workpiece on a rotational axis while the cutting tools remain stationary.

The milling process also allows for the usage of milling machines where both the table and the cutting tools themselves are mobile. This provides greater control and accuracy, with the capabilities to produce flawless surface finishes.

The milling process is best suited for finishing operations so that the final workpiece can have a smooth surface finish, which we achieve by removing material with the help of advanced computer software and precise calculations.

TURNING MACHINING OPERATIONS

CNC Turning operations involve single-point tools and a lathe, which remains stationary. A table then rotates the mounted workpiece at high speed while machine tools or a single cutting tool with sharp teeth cuts through it to create exact measurements and specifications. This process works best for precision CNC machining applications and operations involving minimal cuts with machining tools to produce incredibly precise components and parts.

DRILLING MACHINE OPERATIONS

CNC drilling operations create threaded holes in the workpiece materials using a drill press and other machining tools.Since the bit is a cylindrical shape, this method is ideal for creating hollow tubes or other tube-like shapes with the same diameter as the bit itself. Different sized holes can be made using spotting drills, peck drilling, and screw machine drills but require extreme care during the drilling operations to help prevent drifting, leading, or excess debris in the work area.

GRINDING OPERATIONS

CNC grindinguses a rotating wheel to cut material away from a metal workpiece. This manufacturing process is typically used during the finishing process to produce a high-quality metal workpiece. Different grinders can be utilized depending on the need, including roll grinders, crankshaft grinders, plain cylindrical grinders, or surface grinders.

LASER PROCESSING OPERATIONS

Laser processing refers to using a laser to alter the surface of a material through cutting, drilling, punching, scribing, or heat treatment. Since this is a non-contact processing method, the tool will not generate resistance with the surface of the workpiece. This allows for the laser processing operation to occur at high speed and be applied to different levels and ranges of materials, including both metal and on metals.

EDM MACHINING

Electric discharge machining EDM is a non-traditional process in which the material is removed from a workpiece by a series of electrical discharges between two electrodes. EDM does not use force to remove material but relies on an electric discharge between the workpiece and tool. There are different types of EDM machining, including wire EDM, sinker EDM, and hole drilling EDM. Using the EDM machining process allows for creating shapes and depths that would be impossible to fabricate with a cutting tool and results in a product with a fine surface finish.

PRECISION MACHINING AND MANUFACTURING

Machining and the manufacturing process may seem confusing at first, but they become second nature when you’ve been doing it for as long as we have. Global Mei only uses the highest-quality metals and materials to produce aerospace and turbine gas engine components.

We know how important it is to be unerringly precise in this industry. That’s why we continually evolve our methods to stay up to date with the latest and most innovative CNC machining and manufacturing techniques. Contact us today to request a quote or learn more about how we serve the aerospace and aviation industry.